Our Clean Hydrogen Technology

- Home

- Our Technology

Cost and scale for heating, power generation and chemical applications is a fundamental and long-lasting challenge in the industry. Combining the reliable aspects of chemical reaction engineering with modern electrochemical science, Surrey H2 offers a hybrid water-splitting technology for producing emission-free hydrogen with high efficiency.

How it works

Industry experts from the University of Surrey have invented, developed and patented this innovative yet simple looping system to produce green hydrogen at unbeatable overall system efficiency.

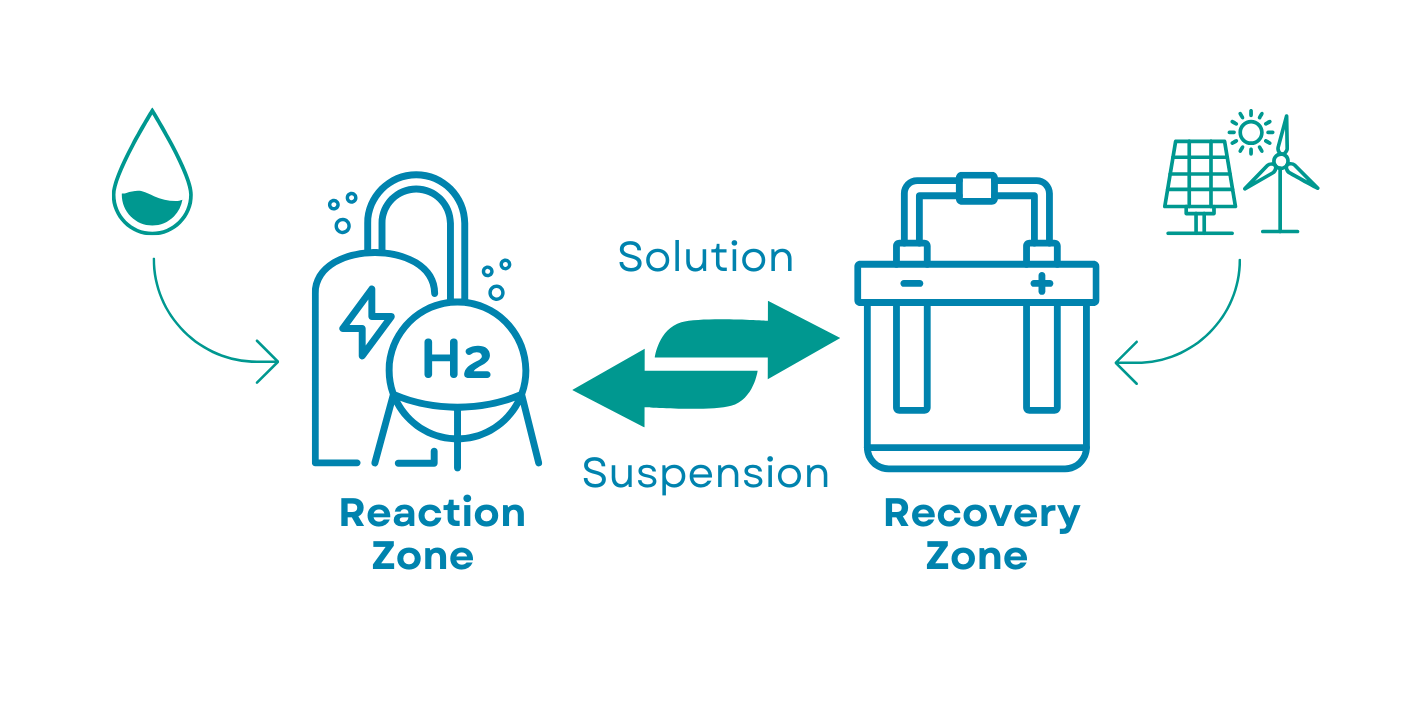

The patented hybrid process is based on thermochemical metal/ metal oxide water splitting technologies, by implementing an electrochemical step to vastly improve efficiency and reduce the very high temperature requirements.

The looping system circulates a metal/ metal oxide which is regenerated using already well researched and optimised metallurgical techniques. The combined system achieves remarkably high operating efficiencies, to produce ultra-low cost green hydrogen gas at high pressure, ready for storage or usage

Why choose Surrey H2?

Cost Effective

Our technolgy can generate green hydrogen more cost effectively than existing technologies.

Works at Scale

Our system is ideally suited for large scale green hydrogen generation which can integrate with other industrial processes.

Self Recycling

Whilst green hydrogen is generated independently, the steam can be recycled to power the system.

Efficient & Robust

Fully automated & robust process with 15-25 years operation. High system efficiency, including pressurised H2.